The Occupational Safety and Health Administration (OSHA), in attempt to improve hazard communication, has adopted new standards for OSHA safety labels. These labels are important for anyone handling hazardous chemicals, including: employees, trainers, distributors, vendors, and OSHA workers among others. By understanding these new requirements, you can not only increase the safety of those who encounter these chemicals (including customers), you can pass OSHA inspection with flying colors. While the new standards will not be fully enforced until July of 2015, it is never too soon to begin preparing for these standards. (And you can switch labelling protocols now if you prefer to get a jumpstart on meeting the new rules!)

OSHA Label Requirements

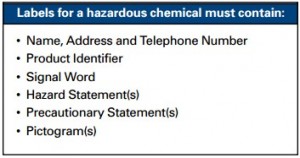

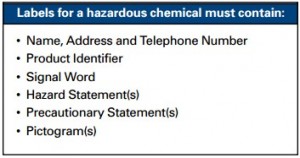

All labels on hazardous chemicals must be clear and readily visible. The label must be attached or printed directly onto the outside of any hazardous materials. First, you must identify the type of hazardous materials before acknowledging the appropriate precautions. Next, the appropriate label can be made. The label must include ALL of the following information:

Label Elements

Make sure that the information is printed clearly and visibly. Also make sure that the following information is present.

-Name, address, & telephone number: This must be the current contact information of the person responsible for the chemical (e.g., chemical manufacturer or importer).

-Product identifier: This is how the chemical is recognized. This should include the chemical name and code/batch number. The responsible party can also include any additional relevant information. The key to this component of the label is consistency, so the product identifier must be the same on the label as it appears in other documents.

-Signal words: This word is linked to the potential dangers of the contained chemicals: “Warning” or “Hazard.” “Warnings” are less hazardous dangers than “Hazards.” A label will only include one or the other classification. As a general rule of thumb, the presence of any hazardous-level chemicals warrant the classification, and label, of “Hazard” (even if there are additional chemicals that only warrant a warning).

-Hazard statements: This section of the label must also include ALL of the potential warnings of a chemical, such as the particular risks associated with the chemicals (e.g., chemical may cause burns to the skins or kidney damage if ingested). Where appropriate, all hazard statements may be combined for ease of reading.

-Precautionary statements: These are the statements that describe the proper storage, handling, and use of chemicals in order to reduce exposure to any potential hazards. Be sure to include all relevant statements: prevention, response, storage, and disposal. In instances where multiple actions are appropriate, a forward slash (/) can be used to demarcate the possible choices.

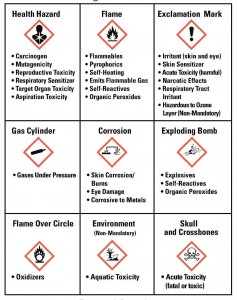

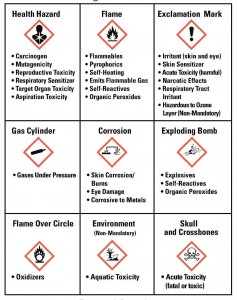

-Pictograms: These graphic symbols are used to improve hazard communication. There are nine graphics that are used for OSHA safety signs. They include: health hazard, flame, exclamation mark, gas cylinder, corrosion, exploding bomb, flame over circle, environment, and skull and crossbones. (For appropriate pictogram use, please see the table of pictograms and hazards.)

-Supplementary information: This is the place on a label in which a responsible party may include relevant information that is not required on a label by OSHA standards. Perhaps additional chemicals (not mandated for disclosure by OSHA) can be included, at the discretion of the responsible party of a chemical, can be placed on this section of the label. Just be careful that any non-required information in this section of the label does not detract or contradict the required label information.

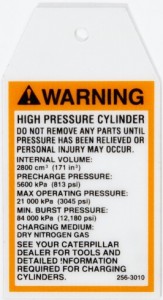

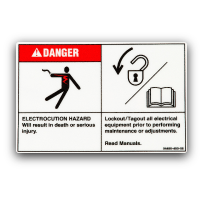

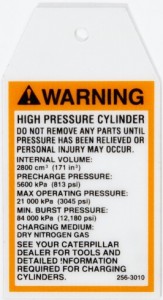

The following is a sample of an appropriate OSHA safety label. (For additional examples, please see the OSHA Brief.)

This is a brief introduction to the improved OSHA safety labels standards being unveiled to improve hazard communication. The information included in this blog is not exhaustive, but instead just a concise broad explanation of what is to be included. Before preparing your own labels, be sure to seek out more specific explanations (particularly as you are drafting your own labels.)

Visit the OSHA Brief for complete information on the Hazard Communication Standard.

You can also streamline your movement to the new OSHA safety sign standards by outsourcing your labels to a company who knows the intricacies of the protocols for safety labels. Feel free to contact U.S. Nameplate for any additional information about developing your new labels.