Metal Nameplates

Our metal nameplates can be fabricated from flexible or metal materials. Screen print, emboss, Metalphoto®, or etch text and graphics onto substrate surfaces. Equipment nameplates can be made to withstand up to 25 years of outdoor exposure and may be die cut, digitally cut, laminated, or machined to your specifications.

Contact UsOrder Custom Metal Nameplates

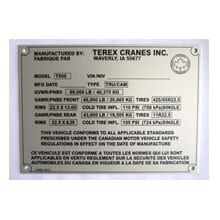

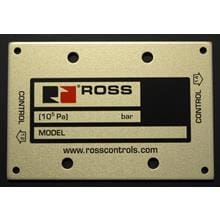

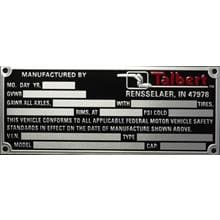

Whatever your metal nameplate needs, U.S. Nameplate Co. can custom design the perfect solution. Our metal identifiers include data and information about weights and equipment specifications. Used in the construction, mining industries, and general equipment manufacturing industries, our nameplates are long-lasting and built to withstand harsh conditions with some products guaranteed for 25 years or more.

Product Gallery

MATERIAL & FINISH OPTIONS

ALUMINUM

.005" - .125" THICKNESSES

- Bright

- Foil

- Mill Finish

- Brushed Finish

ANODIZED ALUMINUM

.005" - .125" THICKNESSES

- Black

- Clear

- Red

- Gold

Metalphoto®

.003" - .125" THICKNESSES

- Matte

- Satin

- Satin Gold

BRASS

.020" - .032" THICKNESSES

- Brushed Finish

STAINLESS STEEL

.010" - .035" THICKNESSES

- 2B Mill Finish

PROCESSES & FABRICATION

- Metalphoto®, Etching, Screen and Digital Printing Available

- Hole Cuts (Any Location) from .05” to 3.5” in Size – varies by material and thickness

- Hole Patterns Machined to Strictest Tolerance

- Up to 25 Year Outdoor Exposure

- UL Listed Products

- Embossing and Forming Capabilities

Design Your Custom Metal Nameplate

Shape and Size

What are the dimensions of your product? Where will the metal nameplate be located/mounted? From what distance would you like it to be seen? These three questions will help you determine the size of metal nameplate needed. Size and shape can also depend on logos or artwork, amount of text, or industry standards. U.S. Nameplate Co. has a number of different dies required to produce special shapes. If our dies do not fit specific needs, custom dies can be created. U.S. Nameplate Co. can die cut, digitally cut, laminate and/or machine a variety of metals in different shapes and sizes.

Materials and Finishes

Because U.S. Nameplate Co.’s customized equipment nameplates are used in industries such as construction, mining, and military, a product that is built to last is extremely important. Additional materials available to create customized metal nameplates includes aluminum, anodized aluminum, Metalphoto®, brass, and stainless steel. Each type of metal varies in thickness, color, and finish options. The two most popular material choices for nameplates are anodized aluminum and Metalphoto. Anodized aluminum is durable, easily maintained, cost-effective, and environmentally safe. All these characteristics make anodized aluminum one of the most widely used materials today for industrial metal nameplates. Metalphoto has been designated as the most durable aluminum substrate available on the market. Here at U.S. Nameplate Co. we produce Metalphoto parts used often in military-grade specifications known to go through some of the harshest conditions.

Color and Finish

Depending on the material used to create the metal nameplate, there are a few different colors available. Anodized aluminum is available in black, clear, red and gold. Almost any metal product stocked can be screen-printed and/or flooded to produce colors specified/needed. U.S. Nameplate Company also has the capability of digitally printing metals to produce photographic quality images. Metal finishes vary between materials but may include matte, brushed, mill, or satin.

Attachment and Holes

How or where will the metal nameplate attach to your product? U.S. Nameplate Co. can place holes in the metal nameplate in almost any location in a variety of sizes. If you are unsure of the best way to adhere the metal nameplate to your product, U.S. Nameplate Co. engineers can recommend the best adhesion method depending on materials, surface and production process.

Request a Quote

Once need is determined regarding customized metal nameplates, continue the process by requesting a quote from U.S. Nameplate Co. When a quote is requested we ask for general company contact information, product need and usage, and a basic blueprint/drawing of the product. It’s our job to help you customize a nameplate best suited to your needs.

Nameplate Fabrication Processes

Embossing

Embossing adds three dimensions to printing for unique identification. The information on an embossed nameplate will remain legible many years after harsh environments wear off any printed image.

Machining

Machining is any one of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. Traditional machining processes, are turning, boring, drilling, milling, broaching, sawing, shaping, planing, reaming, and tapping. Machine tools, such as lathes, milling machines, drill presses, turret punch presses or others, are used with sharp cutting tools to remove material to achieve a desired geometry.

Metal Etching

Metal Etching is a special process used by U.S. Nameplate Co. for products used outdoors. The metal etching process is the most durable process available. This method is recommended for products or machines placed in tough environments and harsh outdoor elements.

Shipping and Application

Total Time Required

At U.S. Nameplate Co., we strive to finish jobs 7-10 days after the proof is approved. In emergency rush situations, U.S. Nameplate Co. is capable of producing expedited orders in 3-5 business days for an additional fee.

Shipping Methods

We ship our products within a 10% over/under quality standard. If an order requires unusual or specific packing, handling or shipping instruction, U.S. Nameplate Co. will accommodate those needs if notified prior to production.

Application

There are many, different adhesive options available to adhere metal nameplates to your product. It is important to consider the texture, surface, and material of the product you will adhere the metal nameplate to. Additionally, the type of adhesive used depends on outdoor exposure, temperature variations and conditions. U.S. Nameplate Co. can help suggest the best type of adhesive for your specific needs.